REQUEST A QUOTE OR MORE INFORMATION

Fill out the form below for someone to contact you reguarding quotes and questions.Or visit our contact page for general contact information.

Feb. 20, 2026

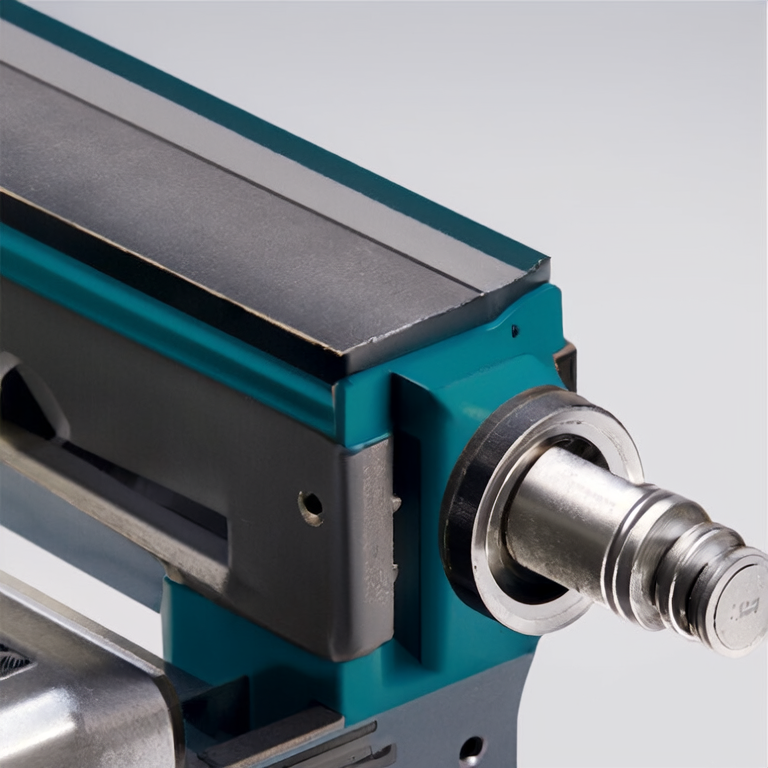

Choosing the right Rotary Cutter Gearbox is crucial for successful bush hog and brush cutting applications. An inefficient gearbox can lead to performance issues and increased costs. With so many options available, it can be overwhelming to select the best solution. This article will explore effective gearbox solutions, key features, and maintenance tips to enhance your brush cutting experience. Image:  Understanding gearbox specifications, durability, and compatibility will help you make an informed choice.

Understanding gearbox specifications, durability, and compatibility will help you make an informed choice.

The **best gearbox solutions for bush hog and brush cutting applications involve selecting durable gearboxes with high torque and efficiency ratings.** Factors like compatibility with your equipment and ease of maintenance are also crucial.

When searching for a gearbox, you will encounter various types. Below is a comparison of the most common gearbox options:

| Gearbox Type | Torque (Nm) | Efficiency | Weight (kg) |

|---|---|---|---|

| Selectors | 200 | 92% | 15 |

| Gear Reducers | 300 | 90% | 20 |

| Industrial | 500 | 85% | 30 |

Selecting the right gearbox involves understanding its features. Here are some important aspects:

Taking care of your gearbox will ensure its longevity and optimal performance. Follow these maintenance tips:

In summary, choosing the right rotary cutter gearbox for bush hog and brush cutting applications is essential for effective performance. Evaluating gearbox types, understanding key features, and implementing maintenance tips will enhance your operation. Invest time in selecting the best gearbox solutions to ensure optimal efficiency and longevity.

Q: What is a rotary cutter gearbox?

A: A rotary cutter gearbox transfers power from the tractor to the cutting blades, allowing efficient brush cutting.

Q: How often should I maintain my gearbox?

A: You should perform maintenance checks regularly, at least before each cutting season.

Q: Can I upgrade my existing gearbox?

A: Yes, upgrading can enhance performance, but ensure compatibility with your current equipment.

Related Products

GEARBOX MANUFACTURER

Zhejiang GTM was established in 1997, which located in economic development zone of Wenling city, southeast of China.

GTM agricultural gearbox products include spiral and straight bevel gearbox, cylinder gear speed reducer, worm reducer, and transmission case etc, which are widely used in various fields as Rotary cutter, grain transportation and storage equipment, Rice harvester,baler,hayrake, rotary tillers, pesticide sprayers, fertilizer spreaders, potato harvester, post-hole diggers, combine harvester,snow-blowers, garden machines and oil exploitation fields etc.

350000+

Annual quantity over

1997

Company establishment

6

Invention patents

56

Utility model patents

REQUEST A QUOTE OR MORE INFORMATION

Fill out the form below for someone to contact you reguarding quotes and questions.Or visit our contact page for general contact information.