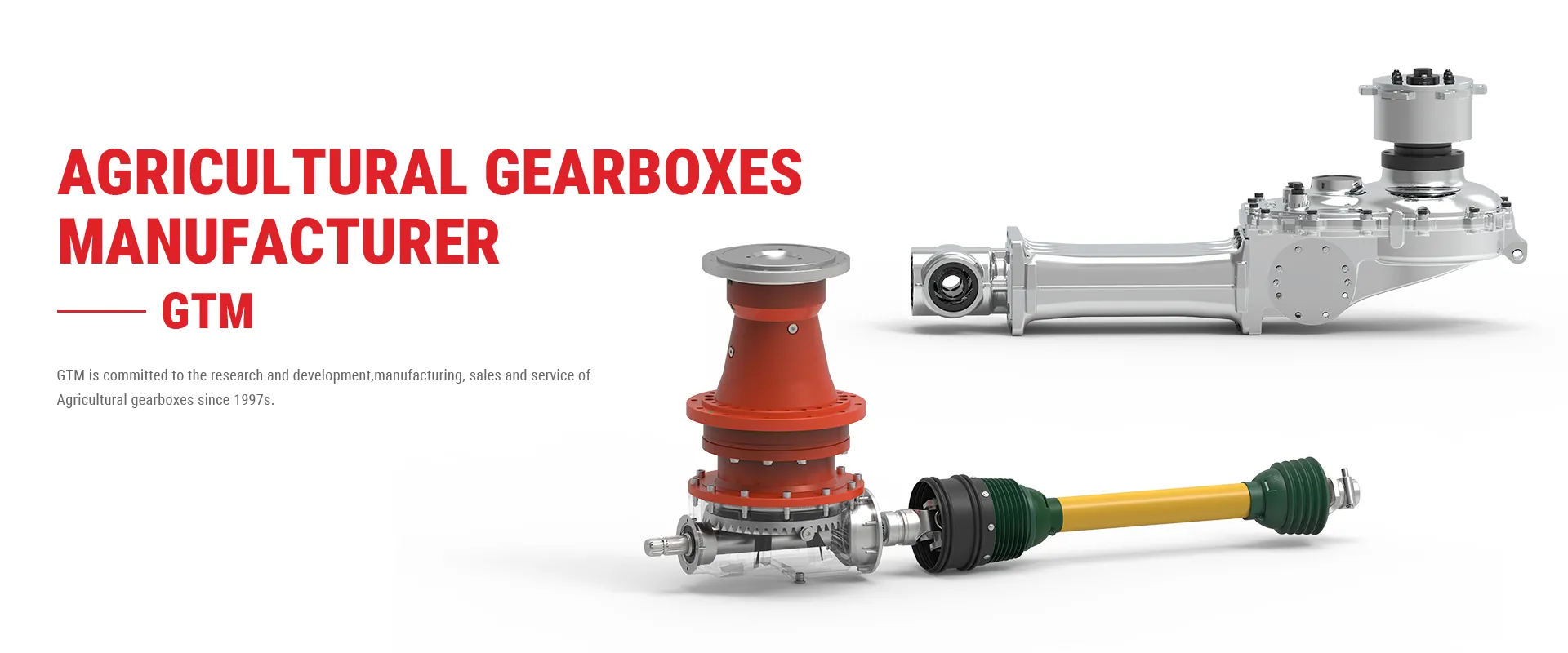

30-300HP

Precision forging gear

All kind of gear ratio can be customized

Multiple Types

Can with Free Wheel Design

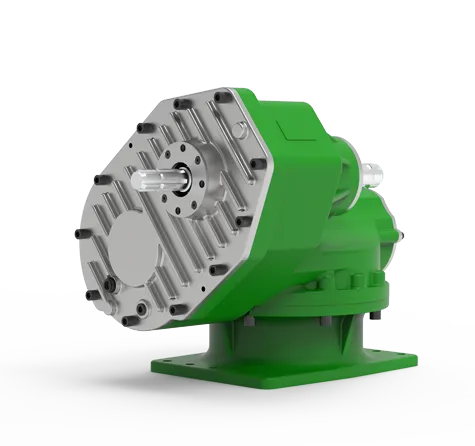

High Performance

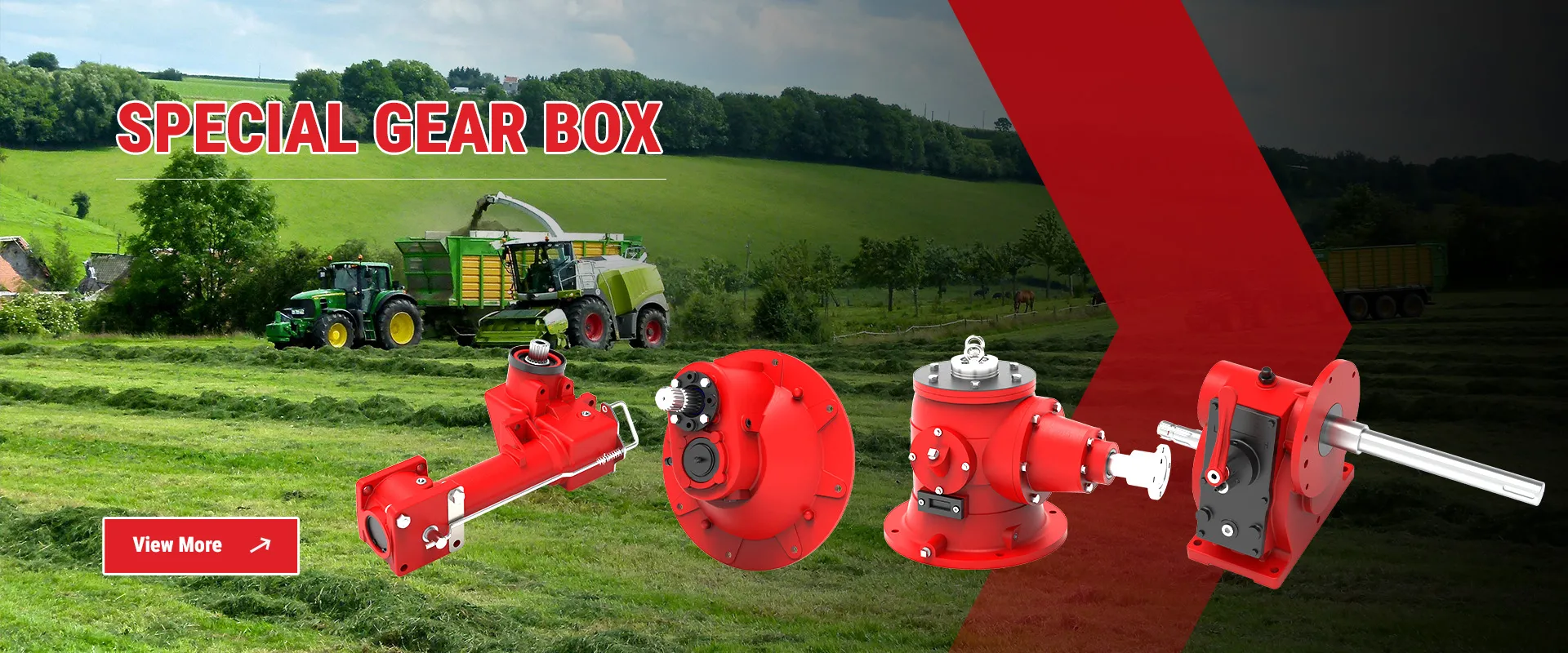

Grain Transportation and Stock Gearbox

Different angle

Special inner design

Long-term running

Combine harvester Gearbox, Baler Gearbox, Snow blower gearbox, Power harrow gearbox....

Cooperating with Top agricultural machines manufacturers.

More than 27 years gearboxes manufacturing experiences.