REQUEST A QUOTE OR MORE INFORMATION

Fill out the form below for someone to contact you reguarding quotes and questions.Or visit our contact page for general contact information.

Feb. 16, 2026

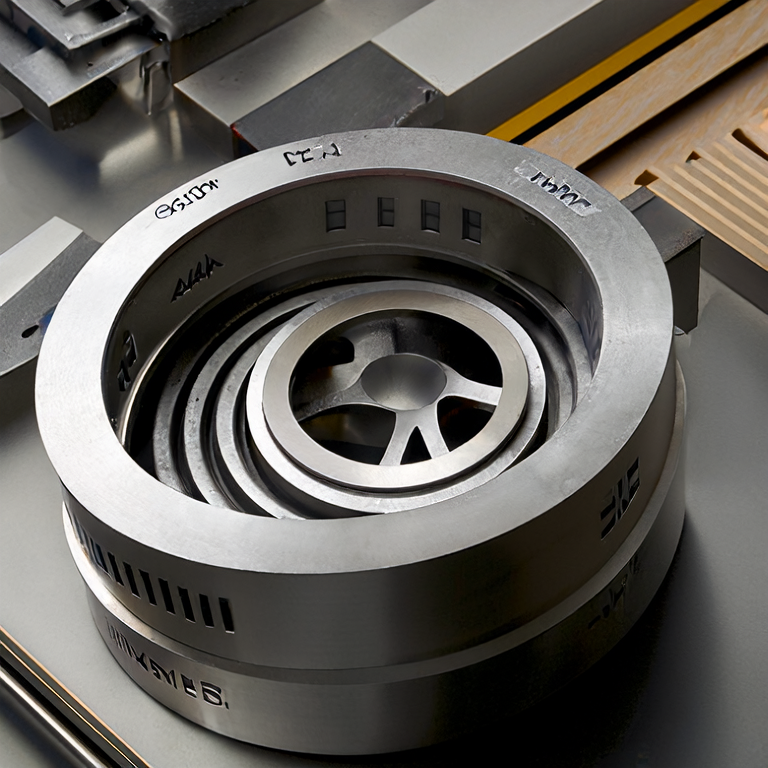

The production of Rotary Cutter Gearboxes involves various challenges. These challenges can impact their quality and effectiveness in agricultural and industrial applications. Understanding how these gearboxes are manufactured is important for customers seeking reliable machinery. This article will explore the process from design to delivery. This includes how each gearbox is crafted to meet export standards. We will cover aspects such as materials used, manufacturing techniques, and quality control practices.

The process of creating rotary cutter gearboxes for export includes design, material selection, manufacturing, assembly, quality control, and finally delivery.

The design phase begins with understanding user requirements. Engineers consider factors such as size, power, and intended usage. This information is vital for creating an effective gearbox.

Prototyping helps in testing designs before mass production. Engineers use computer-aided design software to create detailed models. Physical prototypes may also be created for testing.

Durability is crucial when selecting materials. Steel is commonly used for its strength. Other materials like aluminum may be used for lighter gearboxes.

The choice of materials affects the gearbox\'s efficiency. High-quality materials ensure longevity and reduce wear and tear.

Manufacturing rotary cutter gearboxes requires precision. Computer numerical control machines are used for exact measurements. This ensures each part fits perfectly.

Other techniques used include casting and machining. These methods increase production speed while maintaining quality.

Each component is assembled carefully. Technicians follow strict guidelines to ensure consistent quality. Assembly includes fitting gears, bearings, and housings.

After assembly, gearboxes are tested under various conditions. This helps verify their performance and reliability.

Quality control is a vital step in production. Every gearbox undergoes rigorous testing to meet export standards.

Certification processes ensure that gearboxes perform as expected in the field. This minimizes returns and increases customer satisfaction.

Once quality is confirmed, gearboxes are prepared for delivery. Proper packaging is essential to avoid damage in transit.

Efficient logistics ensure timely delivery to customers. This adds value to the overall service and encourages repeat business.

Understanding the process of creating rotary cutter gearboxes enhances appreciation for this machinery. From design to delivery, each step is critical in ensuring the quality and performance of the final product. By following strict processes, manufacturers can meet the demands of export markets efficiently.

What is a rotary cutter gearbox? A rotary cutter gearbox is a mechanical component that transfers power from the engine to the cutting blades in machinery.

How is a rotary cutter gearbox tested? Gearboxes are tested under various conditions to ensure they meet performance and reliability standards.

What materials are used in rotary cutter gearboxes? Common materials include high-strength steel and aluminum for lightweight designs.

Why is quality control important? Quality control ensures the gearboxes perform reliably and meet customer expectations.

Related Products

GEARBOX MANUFACTURER

Zhejiang GTM was established in 1997, which located in economic development zone of Wenling city, southeast of China.

GTM agricultural gearbox products include spiral and straight bevel gearbox, cylinder gear speed reducer, worm reducer, and transmission case etc, which are widely used in various fields as Rotary cutter, grain transportation and storage equipment, Rice harvester,baler,hayrake, rotary tillers, pesticide sprayers, fertilizer spreaders, potato harvester, post-hole diggers, combine harvester,snow-blowers, garden machines and oil exploitation fields etc.

350000+

Annual quantity over

1997

Company establishment

6

Invention patents

56

Utility model patents

REQUEST A QUOTE OR MORE INFORMATION

Fill out the form below for someone to contact you reguarding quotes and questions.Or visit our contact page for general contact information.