REQUEST A QUOTE OR MORE INFORMATION

Fill out the form below for someone to contact you reguarding quotes and questions.Or visit our contact page for general contact information.

Feb. 18, 2026

OEM stands for Original Equipment Manufacturer. In this context, an OEM rotary cutter gearbox is produced by the same company that manufactures the original equipment. These gearboxes are designed to meet specific standards and specifications set by the machinery manufacturers. Using OEM parts ensures that you receive a product built to fit your machine perfectly, maintaining performance and reliability.

Aftermarket parts are made by companies other than the original manufacturer. These rotary cutter gearboxes are typically produced to fit a wide range of equipment, and while they may offer a cost advantage, they vary in quality and fit. Buyers often consider aftermarket parts for affordability, but it is essential to do thorough research to ensure these products meet the equipment\'s performance needs.

| Criteria | OEM Gearboxes | Aftermarket Gearboxes |

|---|---|---|

| Quality | Designed to original standards | Quality can vary widely |

| Cost | Generally higher priced | Usually more affordable |

| Warranty | Comprehensive manufacturer warranty | Limited or no warranty |

| Availability | Limited to specific models | Widely available |

| Fitment | Perfect fit for machinery | Potential fitting issues |

OEM gearboxes are manufactured using precise specifications, ensuring consistent quality. In contrast, aftermarket gearboxes may lack stringent quality control, leading to variations. Researching brands and user reviews can mitigate risks associated with aftermarket products.

While the initial expense for OEM rotary cutter gearboxes might be high, their longevity often justifies the upfront investment. Aftermarket options can be budget-friendly, however, they may cause additional costs over time due to potential failures.

OEM products typically come with robust warranties, reflecting the manufacturer\'s confidence in their product. In comparison, aftermarket gearboxes may have limited warranty terms, which can be a critical decision-making factor.

OEM parts may not always be readily available for older models, whereas aftermarket gearboxes benefit from broader distribution channels, making them easier to find in many regions.

A significant advantage of OEM gearboxes is their guaranteed fit with original machinery specifications. In contrast, aftermarket parts may not align precisely, leading to potential fitting problems and increased wear on equipment.

Deciding between OEM and aftermarket rotary cutter gearboxes involves weighing quality, cost, warranty, availability, and fitment. While OEM gearboxes guarantee compatibility and reliability at a higher price, aftermarket options may appeal to budget-conscious buyers. Always consider the long-term implications of your choice to ensure optimal performance and machinery lifespan.

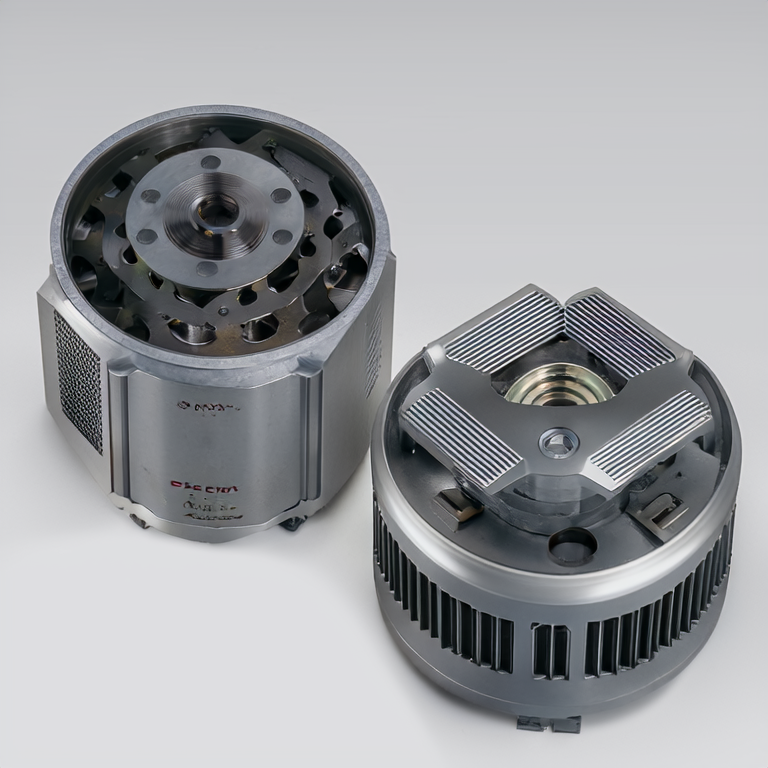

Related Products

GEARBOX MANUFACTURER

Zhejiang GTM was established in 1997, which located in economic development zone of Wenling city, southeast of China.

GTM agricultural gearbox products include spiral and straight bevel gearbox, cylinder gear speed reducer, worm reducer, and transmission case etc, which are widely used in various fields as Rotary cutter, grain transportation and storage equipment, Rice harvester,baler,hayrake, rotary tillers, pesticide sprayers, fertilizer spreaders, potato harvester, post-hole diggers, combine harvester,snow-blowers, garden machines and oil exploitation fields etc.

350000+

Annual quantity over

1997

Company establishment

6

Invention patents

56

Utility model patents

REQUEST A QUOTE OR MORE INFORMATION

Fill out the form below for someone to contact you reguarding quotes and questions.Or visit our contact page for general contact information.