Introduction

Understanding the signs your Rotary Cutter Gearbox needs repair or replacement is crucial for maintaining your equipment. The gearbox is a vital component that transfers power to the cutting blades. If it malfunctions, you may face operational delays and increased costs. Common problems include unusual noises, leaks, and overheating. Recognizing these issues early can save you time and money. Regular maintenance of the rotary cutter can extend its lifespan and improve performance.

Summary Answer

Your rotary cutter gearbox needs repair or replacement if you notice unusual sounds, leaks, overheating, or lack of power.

Signs of Gearbox Issues

-

Unusual Noises

Strange noises like grinding or clunks indicate gearbox problems. Listen for these during operation. Take action if heard.

-

Leaking Oil

If you see oil pooling beneath the cutter, it signals a leak. Check the seals and gaskets for damage. A minor leak can become severe.

-

Overheating

An overheating gearbox can\'t function correctly. Monitor your equipment\'s temperature. If it\'s too hot to touch, investigate immediately.

-

Loss of Power

When the cutter lacks power, it may struggle to cut through materials. This indicates that the gearbox is not delivering sufficient power.

-

Vibration Issues

Excessive vibrations can harm the gearbox and surrounding parts. They may come from worn gears or misalignment. Regular checks can help prevent damage.

-

Visual Damage

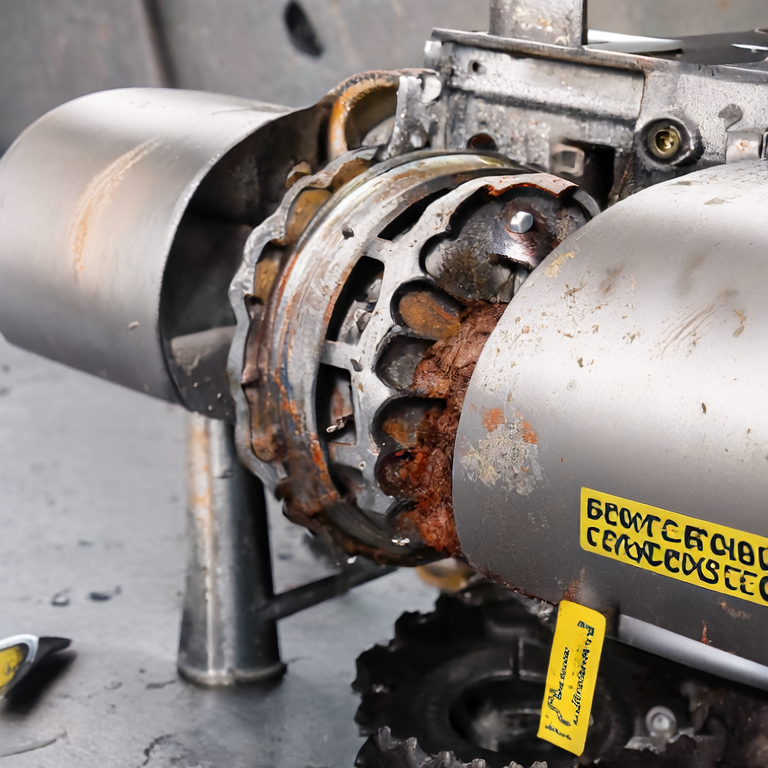

A visual inspection may reveal cracks, dents, or rust on the gearbox. These can affect performance and indicate that repairs are needed.

Conclusion

It is essential to recognize the signs your rotary cutter gearbox needs repair or replacement. Addressing problems like unusual noises, leaks, and overheating early on can prevent severe damage and ensure your rotary cutter performs efficiently.

FAQ

- How often should I check my rotary cutter gearbox?

- Regular checks every few weeks are recommended, especially during heavy usage.

- What should I do if I hear strange noises from the gearbox?

- Stop using the equipment immediately and inspect for damage. Consider consulting a professional.

- Can I replace the gearbox myself?

- While it is possible, it requires mechanical knowledge. If unsure, hiring a professional is advisable.